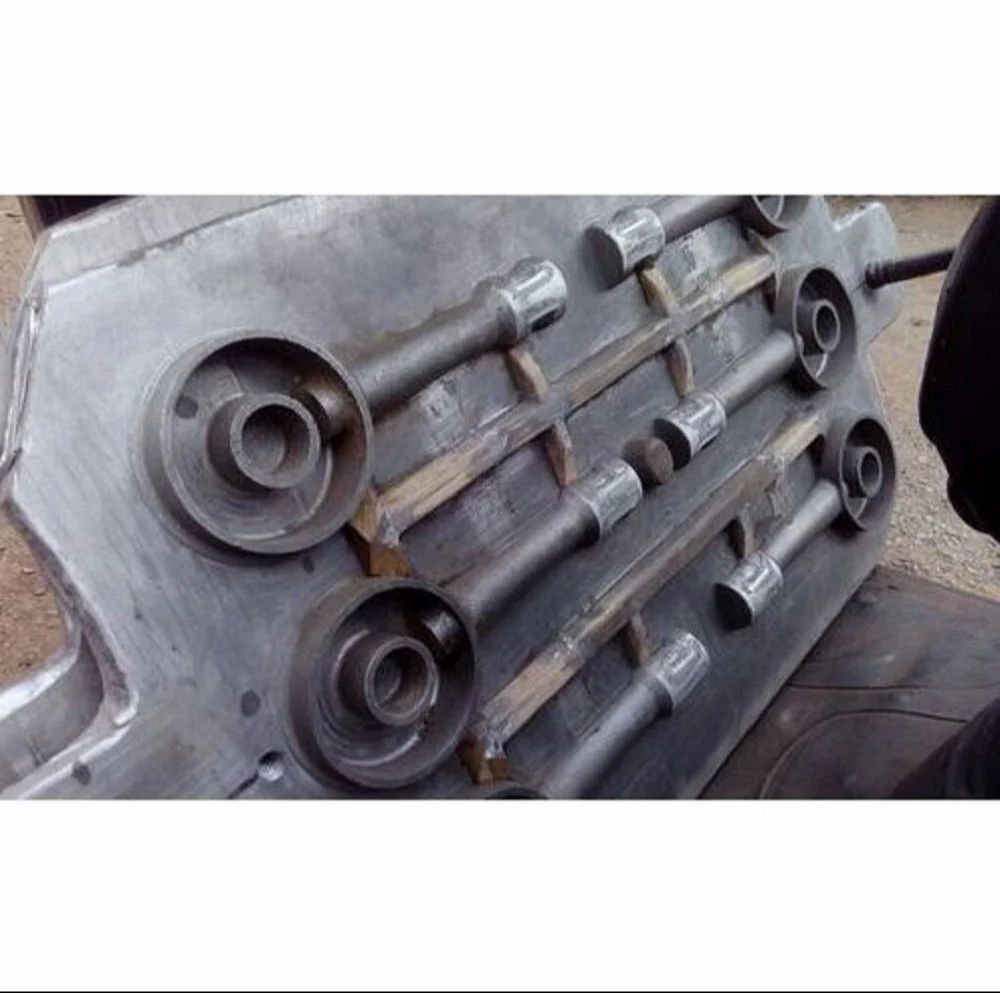

Fairway Sign Aluminium Casting

Price 27 INR/ Piece

Fairway Sign Aluminium Casting Specification

- Usage

- to cast fairway signs maintaining high dimensional uniformity and flawless design

- Casting Process

- Die Casting

- Application

- Industrial

- Product Type

- Fairway Sign Aluminium Casting

- Surface Treatment

- Painted

- Color

- Blue

Fairway Sign Aluminium Casting Trade Information

- Minimum Order Quantity

- 20 Pieces

- Supply Ability

- 10 Pieces Per Day

- Delivery Time

- 1 Days

- Sample Available

- Yes

- Main Domestic Market

- All India

About Fairway Sign Aluminium Casting

Lightweight and compact size of this Fairway Sign Aluminium Casting ensures easy handling, while designing or molding molten metal into the desired shape. This product is used to cast fairway signs maintaining high dimensional uniformity and flawless design. This product is reckoned among customers for its excellent electrical performance and shielding properties at high temperature. This product is manufactured using aluminum by implementing modern molding methods. The offered casting is known for rust resistant, recyclable and convenient usage features. We deliver this Fairway Sign Aluminium Casting at clients' end in various sizes, shapes, finishes and designs.

It seems like youre inquiring about the use of aluminum casting in the manufacturing of fairway signs Fairway signs are commonly used on golf courses to indicate the location and direction of the fairways for golfers If these signs are made using aluminum casting techniques it typically involves the following process

Pattern Creation A detailed pattern or mold is created based on the design of the fairway sign This pattern can be made from various materials such as wood or metal

Mold Making The pattern is used to create a mold This mold is usually made of heatresistant material and is designed to withstand the high temperatures of molten aluminum

Melting and Pouring Aluminum is melted in a furnace until it reaches a liquid state Once molten the aluminum is poured into the prepared mold The molten metal takes the shape of the mold

Cooling and Solidification The poured aluminum is allowed to cool and solidify within the mold This process may take some time to ensure that the metal has completely hardened

Removal and Finishing Once the aluminum has solidified the casting is removed from the mold The casting may undergo additional finishing processes such as sanding polishing or painting to achieve the desired appearance

Inspection The final fairway sign casting is inspected for quality and accuracy Any defects or imperfections may be addressed during this stage

Aluminum casting is chosen for its versatility durability and corrosion resistance It allows for intricate and detailed designs making it a suitable choice for decorative and functional components like fairway signs

Keep in mind that specific manufacturing processes may vary among different foundries or manufacturers and advancements in technology may introduce variations in the techniques used If you have specific requirements or specifications for fairway signs its advisable to work with a manufacturer experienced in aluminum casting to ensure the desired results

Fairway sign aluminum casting refers to the process of creating aluminum castings for fairway signs, which are used in golf courses to provide directional information and course layout details. Here's a detailed overview:

Key Features

Durable and WeatherResistant: Aluminum castings are ideal for fairway signs due to their durability and resistance to weathering, corrosion, and extreme temperatures.

Lightweight: Aluminum castings are lightweight, making them easy to install and maintain.

Customizable: Aluminum castings can be designed to meet specific requirements, including custom shapes, sizes, and logos.

Applications

Golf Courses: Fairway signs are used on golf courses to provide directional information, course layout details, and hazard warnings.

Outdoor Signage: Aluminum castings are suitable for outdoor signage applications where durability and weather resistance are essential.

Benefits

Long-Lasting: Aluminum castings provide a long lasting solution for fairway signs, reducing the need for frequent replacements and maintenance.

Low Maintenance: Aluminum castings require minimal maintenance, making them a cost-effective option for golf courses.

Aesthetically Pleasing: Aluminum castings can be designed to provide a visually appealing and professional appearance for fairway signs.

Considerations

Material Selection: The selection of aluminum alloy is critical for fairway sign applications, with factors such as corrosion resistance, strength, and durability considered.

Design and Engineering: The design and engineering of aluminum castings require careful consideration of factors such as sign layout, font size, and visibility.

Surface Treatment: A surface treatment, such as powder coating or anodizing, can be applied to aluminum castings to enhance corrosion resistance and provide a durable finish

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Aluminium Castings Category

Burner Aluminium Casting

Price 27 INR / Bottle

Minimum Order Quantity : 20 Pieces

Product Type : Burner Aluminium Casting

Application : Industrial

Surface Treatment : Polished

Color : gray

Aluminium Frame Cover Casting

Price 27 INR / Piece

Minimum Order Quantity : 20 Pieces

Product Type : Aluminium Frame Cover Casting

Application : Industrial

Color : gray

Flange Aluminium Gravity Casting

Price 27 INR / Piece

Minimum Order Quantity : 20 Pieces

Product Type : Gravity Casting

Application : Industrial

Surface Treatment : Polished

Color : Gray

BW Body Casting Aluminium

Price 27 INR / Piece

Minimum Order Quantity : 20 Pieces

Product Type : BW Body Casting Aluminium

Application : Industrial

Surface Treatment : Painted

Color : Red

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free