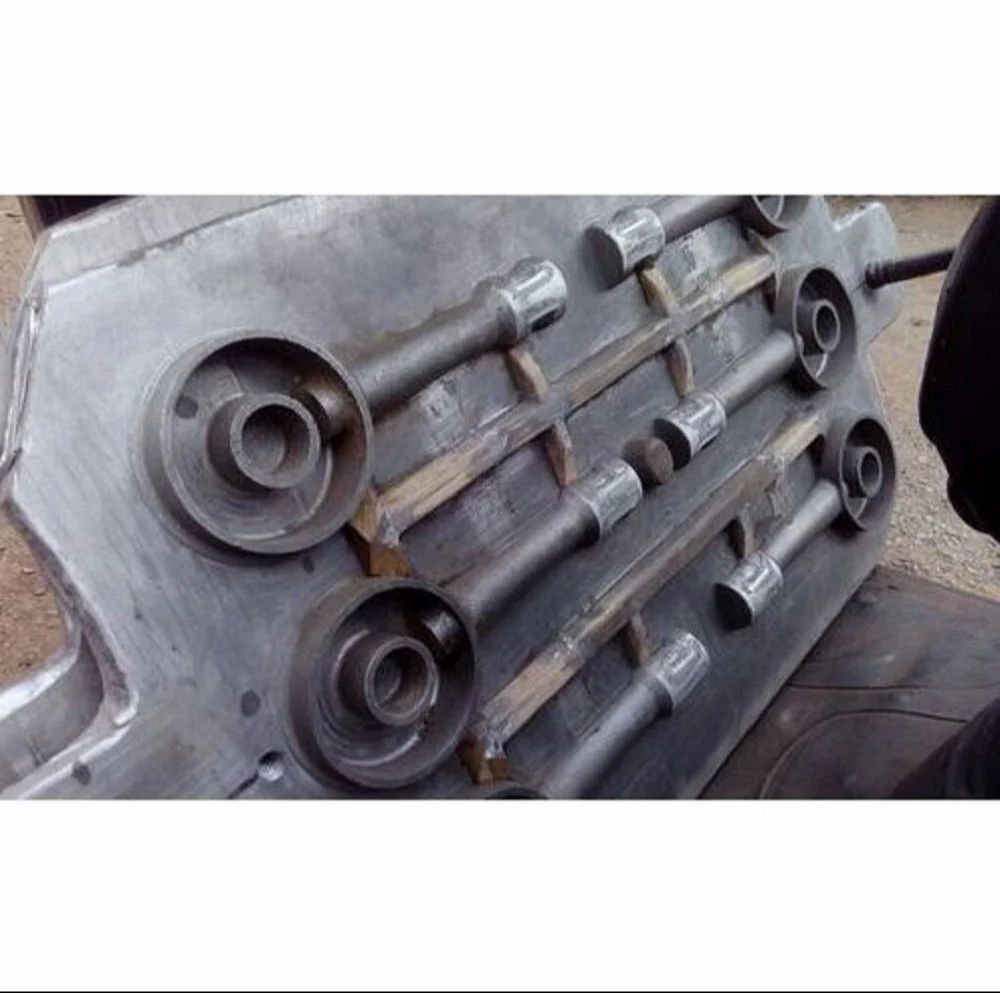

Aluminium Gravity Casting

Price 30 INR/ Piece

Aluminium Gravity Casting Specification

- Height

- 10 Foot (ft)

- Application

- Industrial

- Product Type

- Aluminium Gravity Casting

- Surface Treatment

- Polished

- Weight (kg)

- 100 Kilograms (kg)

- Color

- Gray

Aluminium Gravity Casting Trade Information

- Minimum Order Quantity

- 200 Pieces

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 100 Pieces Per Month

- Delivery Time

- 1 Week

- Sample Policy

- Contact us for information regarding our sample policy

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

About Aluminium Gravity Casting

Customers can purchase this Back Cover Aluminium Gravity Casting from us in various shapes, sizes and finishes. It is extensively used by customers for casting back cover by pouring molten metal into the mold. This casting is known to provide exceptional dimensional stability even in the highest temperature conditions. Each casting has precise dimensions, rugged design and lightweight. Also, the provided casting offers better stiffness and strength-to-weight ratio. This Back Cover Aluminium Gravity Casting is known for improved mechanical and physical properties.

Gravity casting also known as permanent mold casting is a process commonly used in aluminum casting In aluminum gravity casting molten aluminum is poured into a permanent mold under the force of gravity This method is suitable for producing parts with intricate shapes good surface finishes and dimensional accuracy Heres an overview of the aluminum gravity casting process

Mold Preparation

A permanent mold usually made of steel or iron is prepared for the casting process The mold is designed to replicate the desired shape of the final aluminum part

Preheating the Mold

The mold is preheated to a specific temperature Preheating helps in achieving better casting properties and reduces thermal shock when molten aluminum is poured into the mold

Coating Optional

Depending on the casting requirements the mold may be coated with a refractory material or a release agent to enhance the surface finish and aid in the removal of the casting

Pouring

Molten aluminum is poured into the mold The mold is filled under the influence of gravity and the metal takes the shape of the mold cavity

Cooling and Solidification

The poured aluminum in the mold is allowed to cool and solidify This phase determines the final shape and properties of the casting

Part Removal

Once the aluminum has solidified the mold is opened and the casting is removed The casting and the mold can be reused for subsequent castings

Trimming and Finishing

The cast part may undergo trimming or additional machining to remove any excess material or unwanted features Depending on the application finishing processes such as sanding polishing or coating may be applied

Inspection

The final aluminum gravity casting is inspected for quality dimensional accuracy and any defects This step ensures that the part meets the specified requirements and standards

Aluminum gravity casting is often used for producing components such as engine parts automotive wheels and various industrial and consumer goods It strikes a balance between the costeffectiveness of sand casting and the precision of die casting Gravity casting is especially advantageous for parts with complex shapes and where high strength and dimensional accuracy are essential

Aluminum gravity casting, also known as permanent mold casting, is a metal casting process where molten aluminum is poured into a reusable metallic mold under the force of gravity. This method is widely used to produce high-quality, dimensionally accurate aluminum parts with good mechanical properties

Molten aluminum is poured into a preheated metallic mold, typically made of steel or cast iron. The molten metal fills the mold cavity solely under the influence of gravity

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Aluminium Castings Category

Burner Aluminium Casting

Price 27 INR / Bottle

Minimum Order Quantity : 20 Pieces

Color : gray

Product Type : Burner Aluminium Casting

Usage : lame thermal spraying torches of powder materials allow the application of various coatings on a metal surface

Application : Industrial

CW Body Aluminium Casting

Price 27 INR / Bale

Minimum Order Quantity : 20 Pieces

Color : gray

Product Type : Casting

Application : Industrial

Aluminium Frame Cover Casting

Price 27 INR / Piece

Minimum Order Quantity : 20 Pieces

Color : gray

Product Type : Aluminium Frame Cover Casting

Usage : nil

Application : Industrial

Bracket Aluminium Casting

Price 27 INR / Piece

Minimum Order Quantity : 20 Pieces

Color : gray

Product Type : Bracket Aluminium Casting

Usage : manufacturing of brackets for heavy duty equipment for industrial use and appliances for home use

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS